PFA coatings offer both excellent chemical resistance and good non-stick properties. They have high electrical and impact resistance, even at elevated temperatures. Our PFA coating range provides excellent barrier/pinhole-free protection for many aggressive chemicals and highly corrosive atmospheres.

EXPERIENCE & CAPABILITY

As coating experts, we can offer our customers a high-build PFA coating which gives a durable chemical resistant barrier with excellent non-stick

properties.

PFA (Perfluoroalkoxy) coatings melt and flow during baking to provide non-porous films and increased permeation resistance. PFA offers the additional benefits of higher continuous use temperature (260˚C/500˚F), film thicknesses up to 1,000 micrometres, and greater toughness than PTFE and FEP.

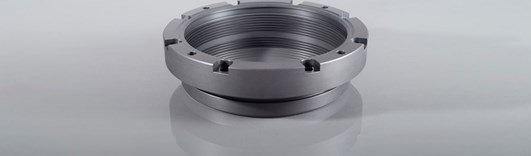

Thanks to our variety of coating types and coating systems, and their versatility, they can be applied to a wide range of substrates including carbon steel, aluminium, stainless steel, steel alloys, brass and magnesium as well as non-metallics such as glass, rubber and plastics.

PFA COATING PROPERTIES

As PFA coatings are available in both water-based and powder forms this gives greater versatility to what type of products can be coated. All aluminium, steel and stainless steel materials as well as many other metallic substrates can be coated with our PFA coating systems.

| Property | Value |

|---|---|

| Operating Temperature range oC | -240°C - 260°C |

| Thickness | 0.2 – 1.00mm |

| Coefficient of friction | 0.1 |

| Colour | Ruby Red |

PFA COATING APPLICATIONS

PFA coatings are used on a variety of products, from the coating of bread pans, dough hoppers and a whole host of industrial bakeware to chemical vessels, pipework systems, agitators, reactors and semi-conductor ductwork.

Non-Stick Release CoatingsOur non-stick release coatings allow the easy release of food, rubber, glue adhesive, or any other type of media from a whole range of applications.