Case Studies

Rotational Mould Coatings

Here is how our non-stick release coatings are used in the process of making tools for rotational moulding.

Making your Classic Kit Car Last

Here is how our zinc thermal spray coating can be used in the creation and restoration of classic kit cards, allowing enthusiasts to break the constant cycle of corrosion.

Non-stick Mould Coatings for Polystyrene Parts

We had a request from customer to see if we could help them solve a problem they had of releasing polystyrene from a casting mould.

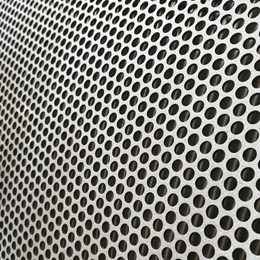

SCREEN PLATES FOR LAUNDRY DRIERS

Here's how we helped our client's industrial engineering team provide refurbishment services for huge industrial laundry drying equipment.

Erosion protection for Coffee Bean Hoppers & Chutes

Our case study looks at how we helped a customer when the OEM coating on their coffee bean hopper started to fail, causing the beans and associated residue to stick to the hopper.

Glue Tank Refurbishment & Coatings

Here's how we helped one of the leading suppliers of finishing equipment to the graphic arts sectors in the United Kingdom and Ireland to refurbish their glue tanks and save money.

Rapid Dough Hopper Recoatings

We were approached by a Fabrication and Service company, whose customers had been having issues with their industrial bakery dough hoppers. They were in desperate need of a rapid recoating service to ensure only minimum factory downtime was required.

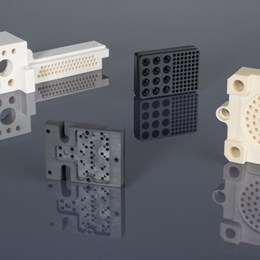

Aerospace Electronics

As a licenced exporter of products for use in the aerospace & defence industry AFT Fluorotec is well qualified to export such goods, but exactly what goods are we talking about here? Why doesn’t the customer simply buy the parts required for the original aircraft manufacturer rather than coming to an independent Fluoropolymer and plastics expert?

Architectural Roof Windows

AFT have successfully provided thermally sprayed zinc coating solutions for windows that are situated in extremely harsh environmental conditions.

Thermally Sprayed Silver Electrical Contactor Coatings

Electrical contactors are normally made from electrically conductive, lower cost copper or alloys of copper. However, copper and copper alloys are prone to corrosion and oxidation.