Our VICTREX PEEK (Polyetheretherketone) coatings consist of AF800 series PEEK powder applied to a substrate to create a protective outer layer. This type of coating is typically used to improve resistance to chemicals, corrosion, abrasion and wear when applied to metal substrates.

Thickness range

Typical AF800 PEEK coating thickness ranges from 300μm to 500μm for powders and 25μm to 75μm for liquid dispersions.

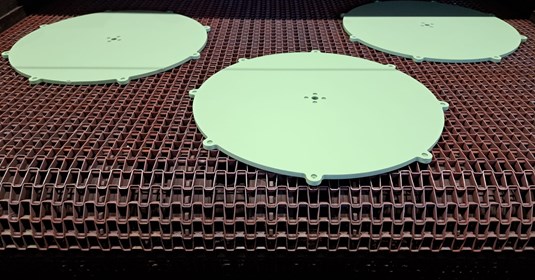

Type of Coating: Electrostatic Coating

Description: PEEK Dry powder consolidated onto parts

Coating Thickness: 100-1000 μm (5-40mil)

Type of Coating: Dispersion Coatings

Description: PEEK powder dispersed in a fluid and sprayed

Coating Thickness: 25-100 μm (1-4mil)

Tolerances of Peek

Typical coating thickness tolerance is ± 25μm on thin coats and ± 125μm on thick coats.

Download the AF800 Series Victrex PEEK Coatings datasheets in the Download Centre

| 20°C / 68°F | 60°C / 140°F | 100°C / 212°F |

|

Resistant

Not Recommended

No Data

|

Resistant

Not Recommended

No Data

|

Resistant

Not Recommended

No Data

|

|

Resistant

Not Recommended

No Data

|

APPLICATION TECHNIQUES

AF800 PEEK powder is typically applied by one of the following methods:

• Electrostatic coating

• Dispersion coating

• Fluidized bed process

Our range of PEEK coatings

We can supply a range of coatings based on VICTREX PEEK Polymer to suit your exact requirements.

• Pure VICTREX PEEK polymer for corrosion and wear

• Combinations with graphite or ceramic for conductivity

• Combinations with PFA, FEP, and PTFE for high-temperature release and friction

PEEK Coatings

Get in touch with our PEEK Coatings team.

Our team are happy to answer any questions you have about using our products and services in your next project. Fill in your details below and we'll be in touch.